Engineering Design Services

Due to the complexity of modern engineering design and the technological landscape shifting so rapidly, manufacturer’s experience challenges familiarizing themselves with every innovation and advancement in every aspect of their product creation.

For example in the medical technology space, it’s overwhelming for a manufacturer to stay on top of the newest innovations in wiring, plastics, metal alloys, electronic components like conductors, software, artificial intelligence, and more, to ensure their product is on the cutting edge within their industry.

With increasing frequency, industries turn to specialized Engineering Houses; Design firms specializing in one specific aspect of the design and manufacturing process, to ensure their product as a whole is on the absolute edge of modern technological advancement and manufacturing materials and processes. Major manufacturers farm out the design and specs of their product to smaller specialized firms to help increase efficiency, reduce cost, and find alternative materials and solutions. Especially during global shortages or market spikes, design houses help increase both profitability and manufacturing lead times.

Minnesota Wire holds a unique position within the manufacturing market. As trusted partners for over 50 years, we help our customers take their conceptual design and create a state of the art new product. As a vertical integrated manufacturing house, Minnesota Wire designs, develops and manufactures wire, cable, and interconnect assemblies. We offer experienced design engineers to ensure your project is conceptualized from start to finish to cut redesign costs, a state of the art research and development program to ensure the latest materials and processes are utilized, dedicated project managers to track the project from start to finish, and in-house testing labs to cut time and costs in the final stages of product design. In this article we’ll discuss what Engineering Design Services are, why they’re so important, considerations prior to hiring a firm as well as why choose Minnesota Wire for not only your manufacturing needs but also your design challenges.

What are Engineering Design Services?

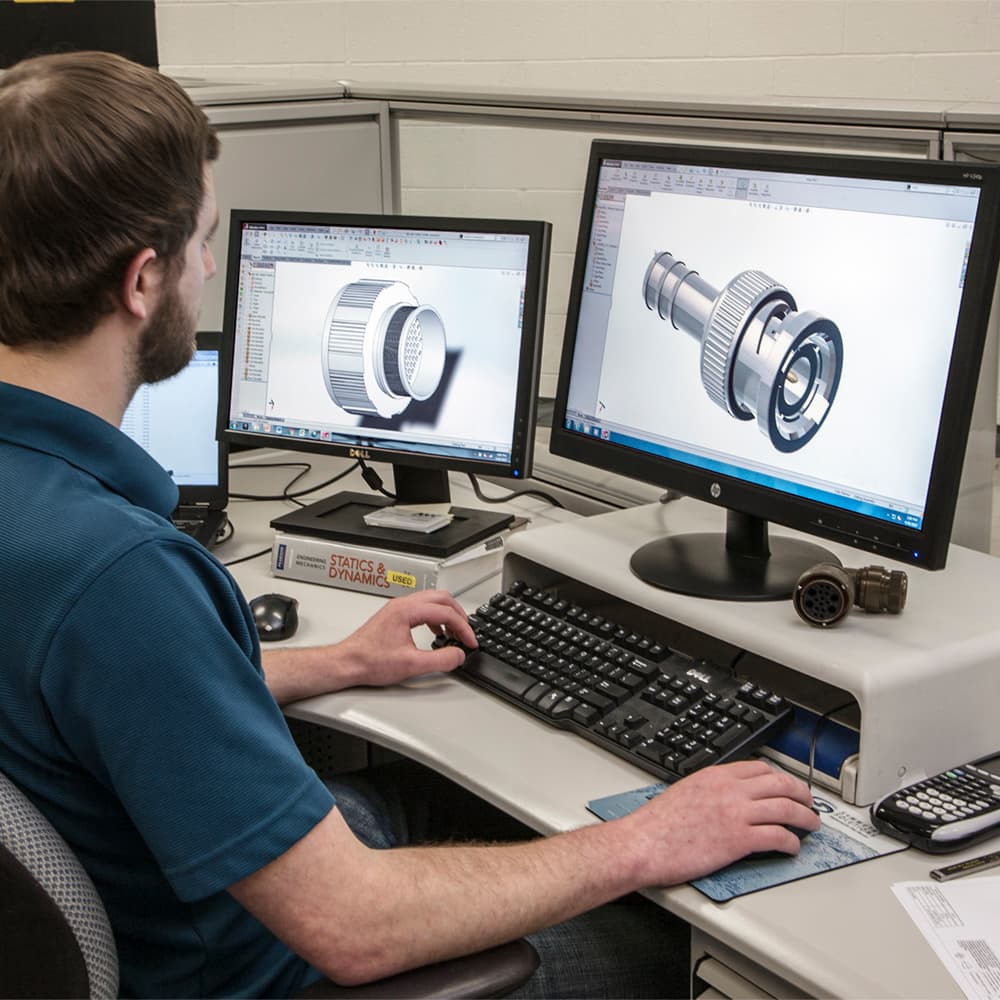

The Engineering Design Process for any new product, in particular high end electronics and new innovative technologies, must be meticulously planned and systematically executed. The process must integrate many different aspects of design so the entire process flows logically and in a comprehensible, efficient way. Much of the software used in the engineering industry grows increasingly complex, customized and specialized to each unique aspect of the manufacturing and engineering process.

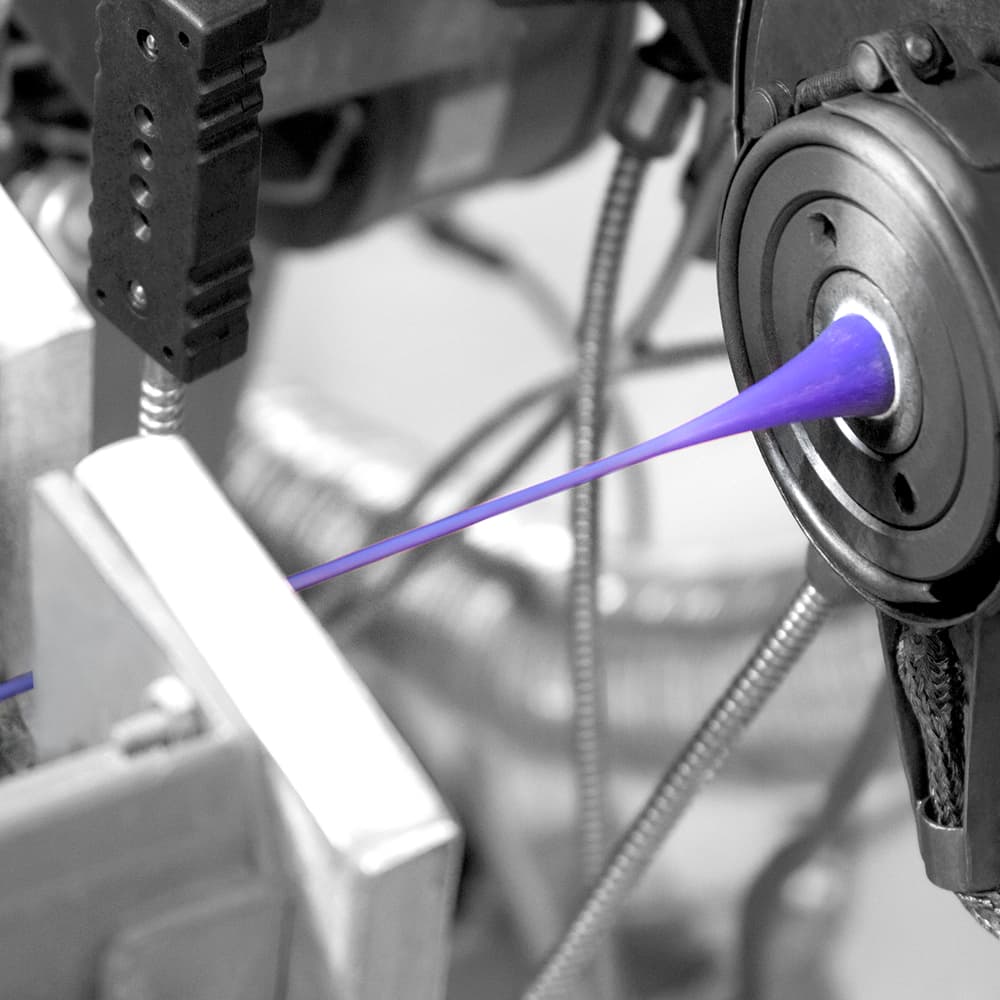

This requires specialized training, not just in the use of these tools, but in the specific understanding of available materials for manufacturing and what those different materials offer.. As a result of the demands of the marketplace, smaller firms specializing in a specific aspect of the manufacturing process have cropped up across the globe. For example, Minnesota Wire excels at designing, testing, and manufacturing high end wire for Medical, Aerospace, Military, and Robotic Industrial applications. Our knowledge of wire manufacturing and technology is unparalleled. Our team of Engineers work with your company to find precisely the perfect kind of wiring, cabling, cable housing, connections, materials, and pretty much anything else wire related for your project. We live and breathe wire manufacturing and technology.

Why are Engineering Design Services needed?

Companies incur high costs hiring specialized engineers, purchase all the specialized equipment and software, and to test using a variety of available specialized materials for each component of the product. Hiring a specialized Engineering Design Firm when creating a new product proves far less costly. These firms already have the expertise, experience, equipment, agility, and access to cutting edge materials that many major manufacturing firms lack.

This is particularly true for mid-tier and specialized manufacturing firms which create or improve upon only a handful of new products each year. The overhead cost for having a wire manufacturing specialist on staff all year round, along with the equipment to manufacture and test the wire designs is significantly higher than the cost to hire an outside firm like Minnesota Wire to do that work for you.

Not only will hiring an Engineering Firm like Minnesota Wire reduce your overall costs during the design and creation process of your product, it will also improve the designs of your product, and help you hone in on the most cost effective manufacturing process and materials for your product. This will help your product get to market faster, and help you meet your manufacturing cost goals far better than doing all of the work in house.

Important Considerations When Choosing an

Engineering Design Service Firm

When hiring a design firm, many factors need to be considered. Here are some tips to help make the process easier for you.

1 – Choose the Firm Offering the Best Value

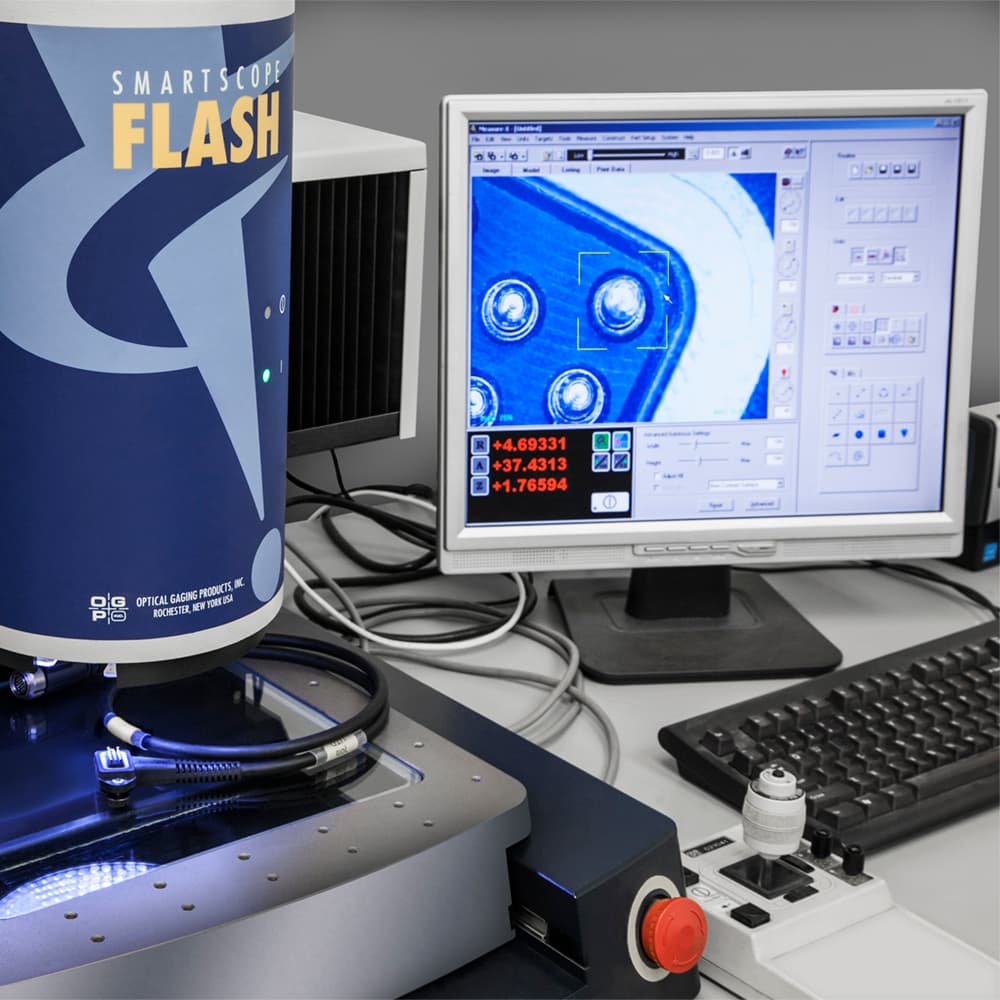

As in all things, the cheapest solution isn’t often the best. Some firms undercut the cost of many of the other specialized design firms in a particular niche marketplace, but do they have a proven track record of success? Are they experienced or are they a new firm? Do they offer comprehensive testing? As trusted advisors for over 50 years, Minnesota Wire offers specialized design engineers and in-house testing thus enhancing our customers experience while reducing farmed out lead times and costs.

2 – Don’t Limit Your Search By Geography

With modern technology and globalization, do not limit your search for a design partner by geographic location. The odds of the absolute best design firm being located right in your backyard is minimal. The best firms work remotely with your team, and are used to it because of the high demand for their top tier services. Minnesota Wire, with locations in St. Paul, MN and Eau Claire, WI, employs a team willing to work with your team’s preference whether in person or remotely to ensure the project is completed correctly within the specified lead time.

3 – Be Aware of Intellectual Property Protections

In the manufacturing world, your Intellectual Property is often your most valuable asset. How will the design firm protect your Intellectual Property? An NDA is all well and good, but how is their IT and E-mail security? What protocols do they have in place to ensure your information is not leaked or released accidentally, or publicly accessible through a security flaw? Overseas design firms and contract manufacturers may not have the same desire, protocols, and policies to protect your Intellectual Property as you do. As an AS9100 (aerospace) certified company, Minnesota Wire’s protocols and procedures adhere to the most stringent industry standards in regards to IT, IP and email security. We understand the desire to protect one’s IP as we hold eight (8) of our own patents on our unique, revolutionary products including iSTRETCH® and carbon nanotube (CNT) cables.

4 – Remember Communication is Everything

Without clear lines of communication between your design team and the Engineering Design Firm, the entire design process implodes. What methods of communication does your potential firm use? How are deadlines and progress updates provided, and how often? Do they assign individual project managers to each and every design job they receive? Will you get the specific specialized attention you need to hit both your design timelines and cost goals? At Minnesota Wire, our project managers ensures we follow the customers preferred methods of communication. In addition, for new projects, we arrange for weekly reviews to discuss the timeline / lead times as well as any cost adjustments to ensure we deliver on time and budget.

5 – Pick a Firm with Comprehensive Services

Ensure the firm processes the knowledge to complete your design requirement from start to finish. You don’t want to hire one company to design the wiring for your new medical device, only to have to then hire a different company to manufacture another part of your medical device. For greatest efficiency and the most cost effective solution, make sure you pick a design firm able to complete the entire project. Minnesota Wire offers all the following in-house services: design and process engineers, experienced tool makers, prototypes prior to large scale manufacturing, extrusion, molding, termination, testing, dedicated project managers, and much more.

Why Minnesota Wire?

At Minnesota Wire, we employ an entire team of expert, specialized engineers eager to help you most effectively design your new product. From conception to construction, we design, test, and manufacture any wire solution your company might need for their newest Medical, Aerospace, Military, Robotics, or Industrial application. Not only do we have access to the world’s most cutting edge wire and cable technologies, we’re actively creating them .

With Minnesota Wire, lean on our 50+ years of experience. Whether it’s designing and engineering, or manufacturing, our team possesses the specialized knowledge, tools, technology and testing to bring your new product to the next level.